About PerMix

PerMix is a cooperative venture with the famous Srugo family in Israel, who have been active and reputed in mixing technology since 1954. PerMix’s has a strong advantage over other competitors!

Product Range

- Solid Blending & Drying Equipment

- Dough Kneading Mixers

- Vacuum Emulsifying Mixers

- High Shear Mixers & Agitators

- Other Process Equipment

Design Capability

Other than supplying our standard product range, PerMix is able to design “tailor-made” process equipment to solve customers' individual problems by translating process parameters into soundly engineered and reliable mechanical equipment.

DON'T KEEP ON GOING ROUND AND ROUND To find out how PerMix can help reduce your costs, call us today on 02476 980833

PerMix Workshop Tour

Products

Powder Blending & Drying

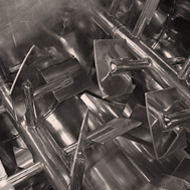

Paddle Mixer

Ploughshare Mixer

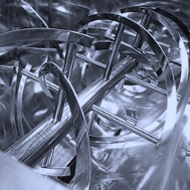

Ribbon Blender

Fluidized Zone Mixer

Conical Screw Mixer

Vertical Ribbon Mixer

High Speed Mixer Granulator

V-shaped Mixer

Double Cone Mixer

3D Mixer

Drum Hoop Mixer

Vacuum Mixer Dryer

Nutsche Filter Dryer

Paste Mixing & Kneading

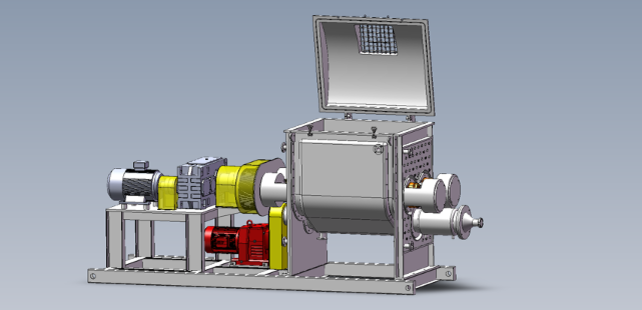

Sigma Kneader Mixer

Double Planetary Mixer

Multi-shaft Vacuum Mixer

Vacuum Emulsifying Mixer

High Speed Disperser

Liquid Dispersing & Mixing

High Shear Emulsifying Mixer

Inline Emulsifying Mixer

Powder Liquid Mixer

Shear Pump

Liquid Agitator

Jet Agitator & Disperser

Contra Rotating Mixer

Magnetic Mixer

Vacuum Deaerator