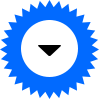

Products

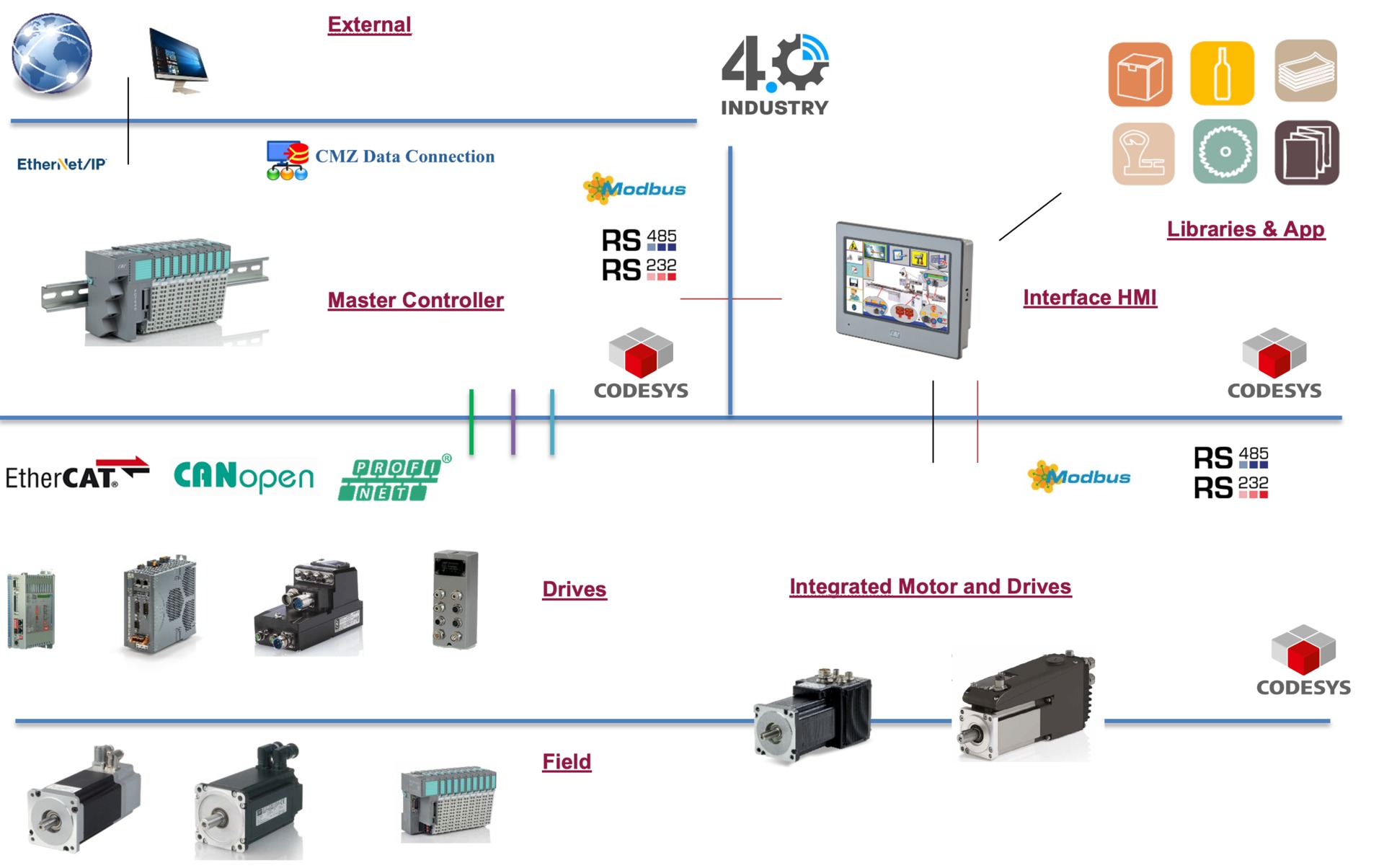

FCT640 Master Controller

Click on this text to edit it.

Processor

CPU: QorIQ T1024, 1 GHz

Memory capability

1 GB Nand Flash 512 MB DRAM

32 KB Ferromagnetic RAM (non-volatile PLC data) EEPROM (Serial no., IP-config) SD-Card

Communication ports

1x RJ45 Ethernet 10/100 MBit (“Debug”/PC/Codesys) 2x RJ45 Ethernet 10/100 MBit (Fieldbus) optional

1x RJ45 CAN-Bus (CANopen Master/Slave) optional

Local I/O modules

64 modules, each with a maximum of 16-bit IO (1024 digital) or 8 channel analog (512 analog)

Fieldbus

EtherCAT Master CANopen Master/Slave ModbusTCP EtherNet/IP/TCP

Fieldbus options:

Everything with software stack offered by CODESYS

Connetivity

Integrated LTE modem

General

Power supply 24V DC

9 LEDs, dual color possible

0° - 60°C ambient temp

FCT200 and FCT300 Master Controller

FCT200 Master Controller

FCT300 Master Controller

Up to 8 axes real - time via CANopen

Communication ports:

RS232, Ethernet, RS422-485, SMI port

Field BUS on board:

up to 2 CANopen ports

Optional Field BUS:

Profibus-DP slave

Mass memory:

SD card

Up to 99 axes real-time via CANopen & EtherCAT

Communication ports:

RS232, 2XEthernet, RS422-485, SMI port

Field BUS on board:

2 CAN ports, 1 EtherCAT port

Optional Field BUS:

2xCANopen ausiliary, 2x Ethernet port , Profibus DP slave, DeviceNet, Ethernet/IP

Mass memory:

1xSD card, 1X internal, SD card

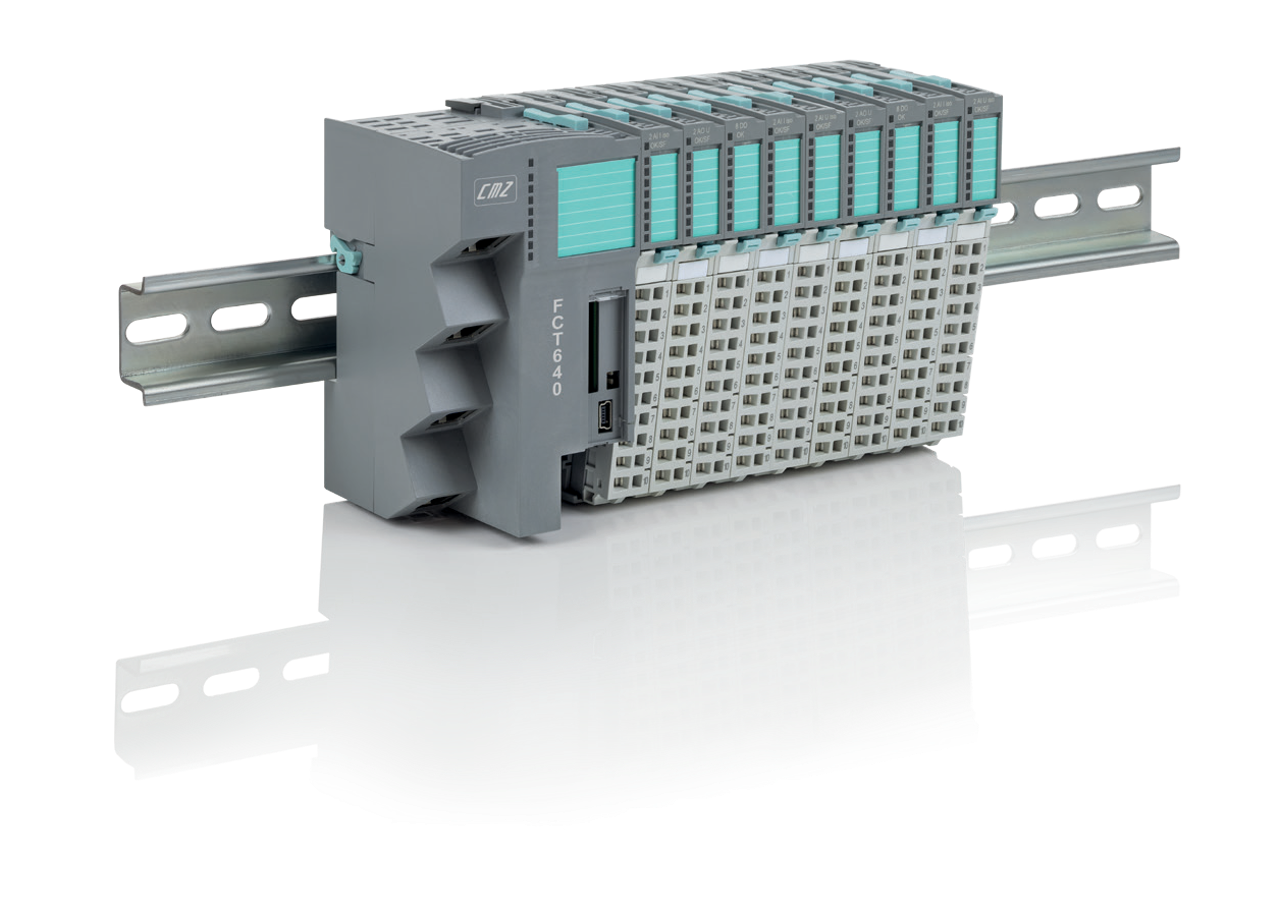

Servo Drives

LBD Servo Drives

Brushless drive with CANOpen and EtherCAT interface

From 5 to 75 A nominal

230 and 400 Vac

Feedback: Resolver or absolute/incremental encoder

Encoder OUTPUT or second encoder INPUT

STO

SBD Servo Drives

Brushless drive with CANOpen EtherCAT and Pofinet* interface

From 5 to 20 A nominal

230 and 400 Vac

Bluetooth Control*

Feedback: Resolver or absolute/incremental encoder

Encoder OUTPUT or second encoder INPUT

STO

Self Software Environment

Servo Motors

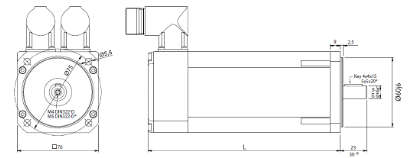

MMB/D/S Servo Motors

TORQUE RANGE

From 0,25 to 300 Nm stall torque

TORQUE POWER

From 0,15 to 80 kW

POWER SUPPLY

48 / 230 / 400 V AC

SPEED

From 1500 to 6000 rpm

FLANGE

From 40 to 230 mm

FEEDBACK

Resolver / Incremental / Absolute – Hyperface / DSL

OPTIONS

Brake / Flywheel / IP67

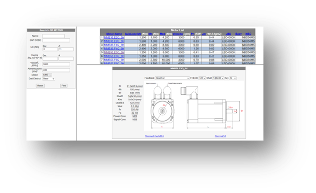

ONLINE CONFIGURATOR

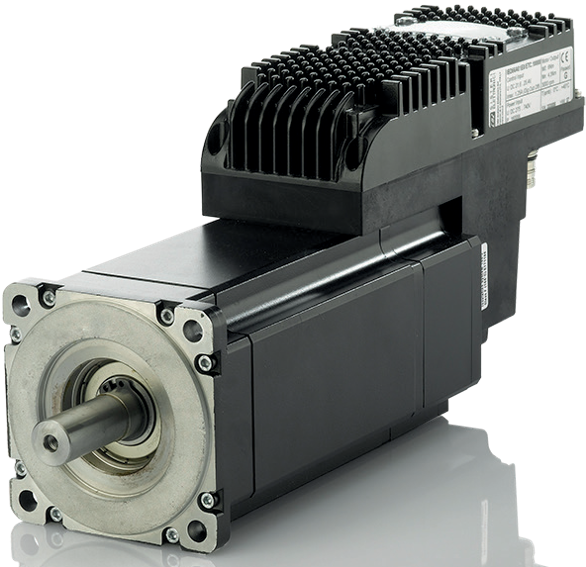

IBD: Integrated brushless drive

Power supply

275 ÷ 730Vdc (560Vdc Nominal)

Logic supply

24 Vdc

Torque range

Stall torque 1,3-1,5-2-4-5,6-6-8-15-30 Nm,

Rated speed

Vn=5000 rpm (for 1,3Nm)

Vn=3000 rpm (for 1,5-2,8-4-5,6-6-15-30Nm

Interface

EtherCAT, CANopen

Safety

for size 1,3Nm:

STO 2 channels, SIL3 (pending) for sizes from 1,5Nm to 30Nm:

STO 1 channel, SIL3 PL ‘d’ category 2

Feedback

HIPERFACE absolute encoder single or multiturn On board I/O’s

for size 1,3Nm:

3 digital inputs PNP 24V 2 digital output PNP 24V

1 pogrammable input/output PNP 24V

for sizes from 1,5Nm to 30Nm:

6 digital IN 24Vdc general purpose, configurable as: PSTOP, NSTOP, Enable, Home, Capture

3 digital OUT 24Vdc 250mA, general purpose

1 digital IN/OUT 24Vdc with configurable function

3 differential I/O’s configurable as master incremental encoder and Step/Direction

1 analogue IN +/-10V

Protection

IP65

Option

Internal brake

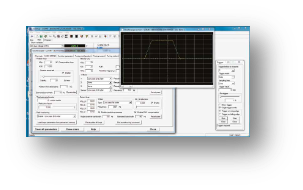

SOFTWARE ENVIRONMENT

SD Setup

NBD: Near by Servo Drives

Drive IP65 for linear and rotating brushless motors

Power supply

275 ÷ 730Vdc (560Vdc Nominal)

Rated current

8Arms

Peak motor current

15Arms

Logic supply

24Vdc

Protection

IP65

Security

STO 2 channels

Input/Output

3 digital inputs PNP 24V 2 digital outputs PNP 24V

2 digital input/digital output bidirectional PNP 1 analog input +/- 10V

Encoder master input + 5V out

SOFTWARE ENVIRONMENT

SD Setup

SVM: Stepless servo drive & MM stepless motors

Interface: CANOpen, Profibus DP,

±10V, RS485 Modbus, pulse/direction

Profiles of speed, position and torque

Internal PLC programmable in IEC61131

dedicated and general purpose IN/OUT’s

Motors sizes

Available up to 21Nm

DC power supply up to 160 Vdc

SOFTWARE ENVIRONMENT

SD Setup

ISD: Integrated Stepless drive

Up to 12Nm, DC power supply up to 135 Vdc

Interface: CANOpen, Profibus DP, ±10V, RS485 Modbus, pulse/direction

Profiles of speed, position and torque

Internal PLC programmable in IEC61131 dedicated and general purpose IN/OUT’s

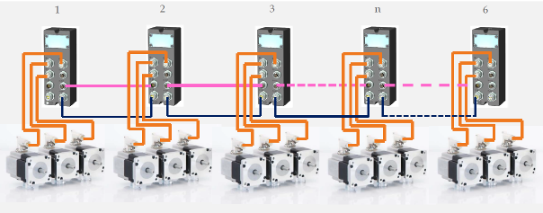

TSC: Near by Servo Drives

Drive for 3 stepper motors

Power supply

48 Vdc

Protection

IP65

Input

1 analog input +/- 10V

Daisy chain

up to 6 devices

Stepper motors size 60 mm

Torque

1,65 and 3,1 Nm

Feedback

Absolute single turn encoder

PT Series: HMI

HMI pannel

Consist of premium level panels.

Available sizes: from 4,3” to 15” LCD display

TFT-LCD

Embedded touch system

16-bit

LED

From 250 to 450 cd/m2

CPU RISC ARM9 32 bit

Working Memory 64 MB

USB

SOFTWARE ENVIRONMENT

Panel master designer

CP4PWM: Solution for managment vibrating channels

Control of 4 channels not depending from frequency and main voltage

Adjustment during installation

Fast self-search of resonance frequency

Automatic calculation of the impressed voltage

Movement dynamic regulation

Boost start for product release

Soft Start for silent start

Fast stop of the vibrator for reduction of the product queque

Programmability

Stand Alone with IEC61131 programmability

Supply voltage

110/230 Vac 50/60 Hz

Maximum output power 600W/channel

Maximum output power of the system 1,4 kW @ 230 Vac ,

700 W @ 110 Vac

I/O

8 digital pnp input, 8 digital pnp output 24V 500 mA,

2 analog output 4-20 mA, 4 analog input 4-20 mA

Features

Fanless, electronically protected against overheating,

configuration trough USB

SOFTWARE ENVIRONMENT

SD Setup