Yaskawa AC Drives

Yaskawa drives incorporate the latest technological advancements in variable speed AC motor control, made possible by experience and dedication to quality.

With manufacturing facilities in the United States, United Kingdom, Japan, China, and other countries, Yaskawa is the world’s largest manufacturer of variable speed drives, providing solutions through 2250HP. From simple to complex applications, Yaskawa has a variety of drive products to fit your needs.

At home in any application.

DON'T KEEP ON GOING ROUND AND ROUND contact us for more information about the Yaskawa range of drives Tel 02476 980833

YASKAWA has extensive knowledge and many years of experience in automation with more than 22 million YASKAWA AC drives installed

worldwide. Thanks to the high manufacturing quality and the design for long, maintenance-free operation, they perform their work discretely for many years.22

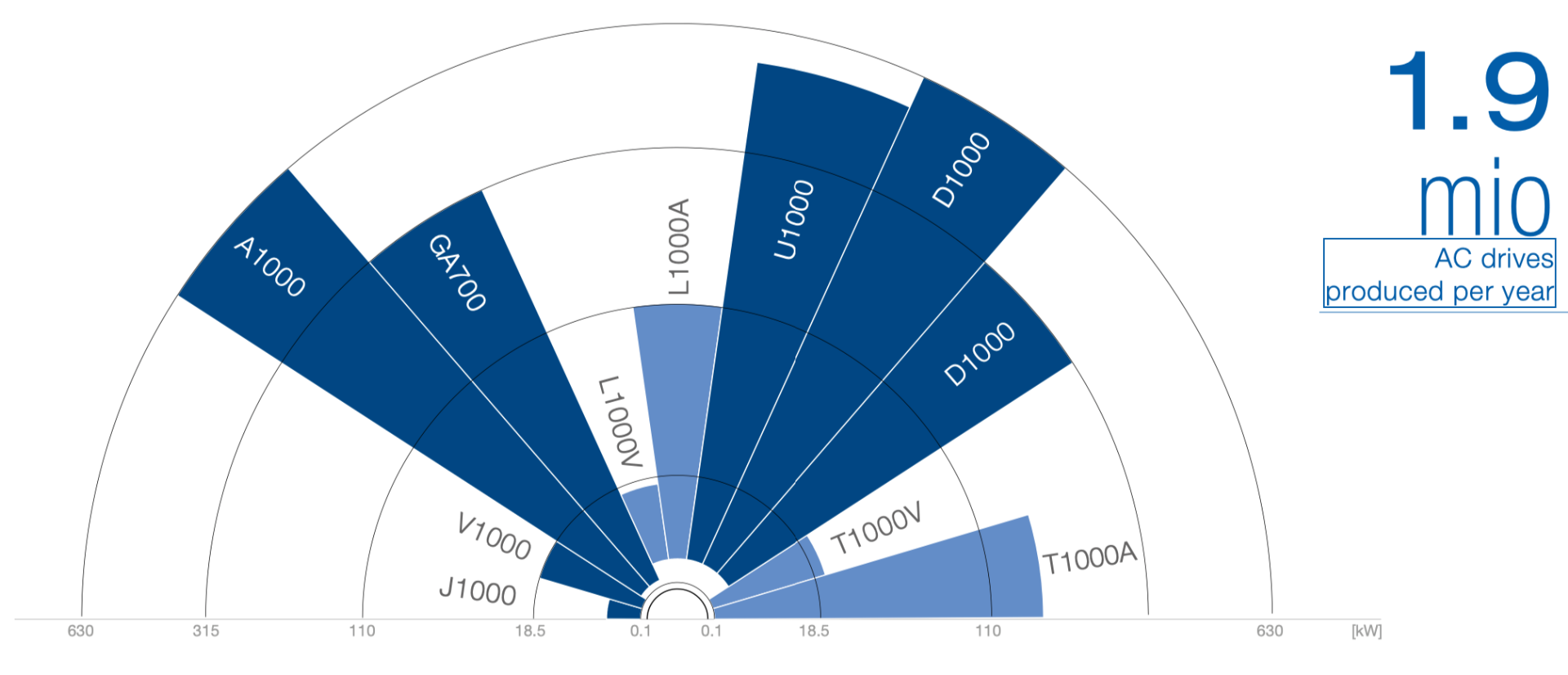

Power range & versatility 1.9 million AC drives produced per year, 22 million AC drives in the field.

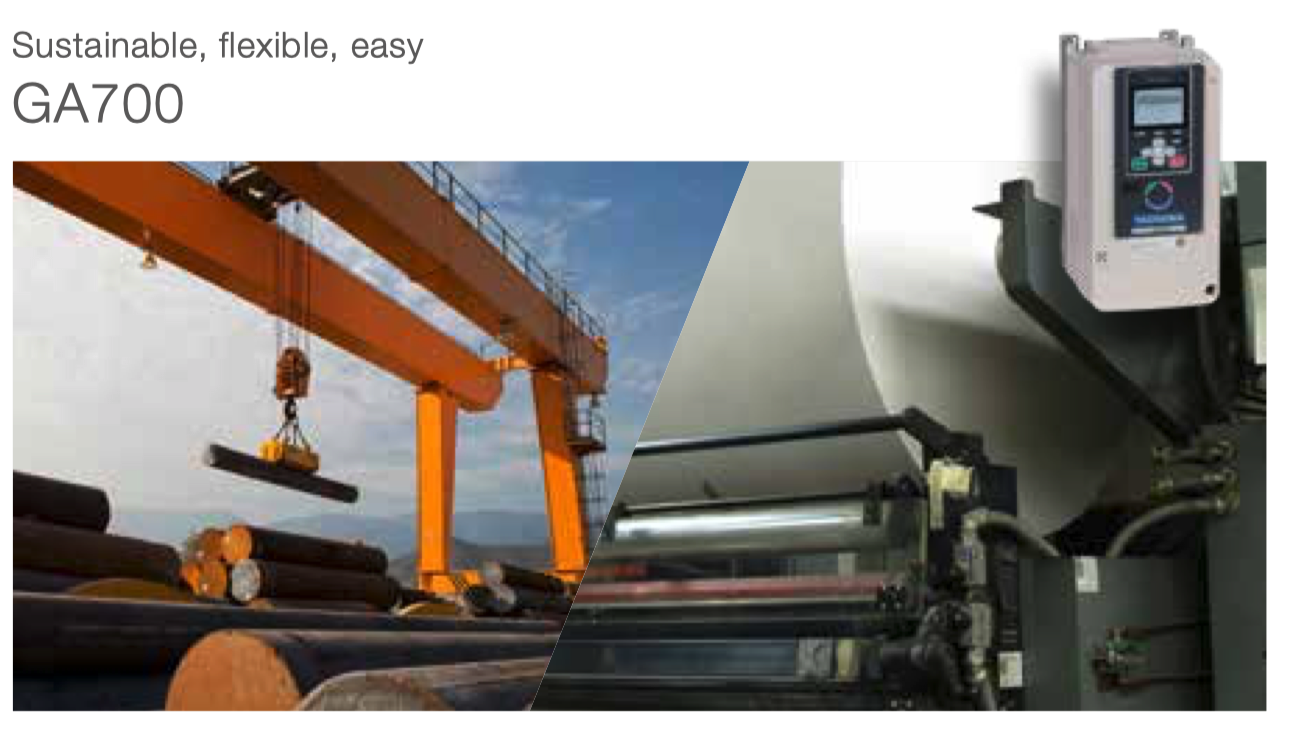

GA700 Limitless possibilities

Incredibly reliable, easy to use and powerful!

Your time is valuable. That’s why we’ve designed this variable speed drive to meet all your needs. Offering world class YASKAWA quality, along with intuitive interaction and high flexibility, our new GA700 is meant to easily handle nearly any application.

Discover the limitless possibilities of GA700!

Extensive possibilities with the latest technologies

The GA700, developed for the control of conventional and new motor technologies, is suitable for applications ranging from simple fans and pumps to powerful test benches requiring precise control, thanks to its power range of up to 355 kW. The GA700 offers a wide range of options, whether you need hard wired discrete, analog or advanced network control.

DON'T KEEP ON GOING ROUND AND ROUND contact us for more information about the Yaskawa range of drives Tel 02476 980833

Wizards and apps for easy configuration

Just as impressive as its rugged, powerful and flexible design are the high-resolution display, configuration wizards and available mobile apps. All of this, along with advanced safety methods and a variety of environmental solu- tions, make the GA700 the optimum choice for variable speed control.

GA700 Benefits and Features:

Easy network integration

• Networking of up to five GA700 AC drives with only one network card

• Maintain network communication even in case of main power failure

One for all

• Precise control of asynchronous, permanent magnet or synchronous reluctance motors via a single AC drive without the need for motor auto-tuning

Meets global standards

• Local/global standards

• RoHS compliant

Powerful configuration tools

• DriveWizard® and DriveWorksEZ® are PC tools for drive management and logic programming

Quick and easy setup

• Reduce setup time with an intuitive keypad, navigation and start-up wizards

Flexible package design

• Designed with flexibility to simplify installation and cabinet design

Integrated functional safety

• Increased safety and reliability with STO SIL3 functional safety

Convenient setup and monitoring

• Safe programming without main power connected

• Cloud-connected DriveWizard® Mobile app for drive management on smart phones and tablets

• Optional Bluetooth control panel allows full access to parameters even when the switch cabinet is closed

A1000 High performance multi-purpose AC drive

The YASKAWA A1000 AC drive provides remarkable advantages through excellent motor drive performance, environmental benefits and energy savings as well as many user-friendly operating features.

DON'T KEEP ON GOING ROUND AND ROUND contact us for more information about the Yaskawa range of drives Tel 02476 980833

A1000 IP54 Ready

Click on this text to edit it.The IP54 Ready drives are the optimal solution for small sized custom panels with a high degree of ingress protection.

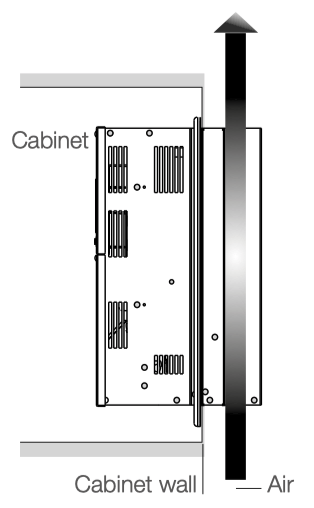

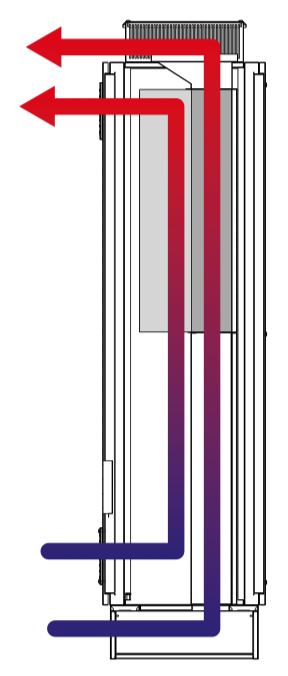

• Heatsink out of the back mounting with IP54 sealed mounting flange brings main heat loss out of the panel and allows smaller panel dimensions

• Easy out of the box installation of single and multiple drives in a single panel

• Low soiling of electronic components

The waste heat from the A1000 IP54 Ready is dissipated by natural air circulation outside the control cabinet.

A1000 IP54 Wall Mount

The IP54 Wall Mount drives are made for decentralized installation.

• A1000 in IP54 compliant panel with door mounted LCD keypad

• Built-in EMC filter, optional IT grid filter

• No extra panel needed, simple installation to machines or rooms

• Mains switch optionally built-in

• Space for additional components allows customization

DON'T KEEP ON GOING ROUND AND ROUND visit us for all your electric motor related needs

A1000 Benefits and Features

• Excellent motor drive performance

- A1000 is a premium AC drive running induction motors and also PM motors in open and closed loop mode with full torque at zero speed

• Easy integration of PLC functionality with DriveWorksEZ engineering platform

• Full text display (13 languages) and automatic motor tuning for easy and time-saving start-up

• Dual rating (HD/ND)

• Outstanding reliability with long life design for 10 years of maintenance free operation

• Encoder interfaces and I/O interfaces for higher flexibility

• Functional Safety integrated (STO,SIL2, PL-d)

• Solutions for positioning, high output frequency applications, winder, electronic line shaft and cranes

A1000 IP23/IP54 Floor Standing Panel

Pre-configured according to customer requirements and installed in the control cabinet, the drive system is instantly ready for use.

• Reliable

Thermally, mechanically and elec-tronically tested (LVD/EMC), no need for customer tests

• Simple

Complete working system from one supplier, only one partner for service and support

• Time saving

Easy procurement, fully pre-assembled and ready for wiring, fast commissioning and setup

• Innovative

Separate air ducts for power section and control section ensure optimal cooling and reduce contamination of electronic parts

• Flexible

Easily adaptable to individual customer requirements

Click to enlarge

The A1000 IP23/IP54 Floor Standing Panel is passively cooled using two separate air streams.

EMC filter

Communication options

Options for power input

Fuse protection or automatic line circuit breaker

Options for drive output

Motor chokes, sinusoidal filters, etc.

Braking option

I/O and speed feedback option

Customized option bay, for customer specific extensions like PLC, power supply...

Fully configurable to customer needs, ready to use. No further tests or configuration necessary.

DON'T KEEP ON GOING ROUND AND ROUND contact us for more information about the Yaskawa range of drives Tel 02476 980833

Applications for the A1000

The YASKAWA A1000 AC drives can be used in a broad range of applica- tions - even in harshest environments.

• Compressors

• Winders

• Cranes & hoists

• Extruders

• HVAC

• Conveyors

V1000 Compact and powerful AC drive

The YASKAWA V1000 is a general purpose AC drive covering the demands of a wide field of applications including Open-Loop-Vector functionality and the usage of PM motors without feedback.

V1000 Benefits and Features

• Drives induction motors and also permanent magnet motors in open loop control

• Overload of 150% / 1 minute for heavy duty applications. Operates one size larger motor in normal duty

• Functional Safety integrated (STO,SIL2, PL-d)

• Easy integration of PLC functionality with DriveWorksEZ engineering platform

• Energy-saving control and operation of highly efficient PM motors for optimized machine efficiency

• Auto-tuning function and simple parameter structure for easy and time-saving start-up

• Space saving and compact design side-by-side mounting possible

• Outstanding reliability with long life design for 10 years of maintenance free operation

DON'T KEEP ON GOING ROUND AND ROUND contact us for more information about the Yaskawa range of drives Tel 02476 980833

V1000 IP66

Decentralized solution for variable speed and simple positioning applica- tions without cabinet with the proven reliability of the V1000 AC drive.

Perfect for wet and dusty working envi- ronments that are cleaned with water streams.

• Available in two enclosure versions

1. Built-in LED operator panel for

best readability and handling with gloves

2. Blank face plate, RJ45 connector for external operator connection

• No need for costly enclosures against dust, water, oil or other environmental stress

• Easy installation and wiring

• Additional accessories find their place within the enclosure

• Integrated class C1 EMC filter

Applications for the V1000

The compact and powerful design of the V1000 AC drives helps to reduce the overall size of the system while continuously delivering peak performance.

• Conveyors • Fans • Refrigeration compressors • Pumps • Washing machines • HVAC • Water treatment • Ceramics industry

J1000 The easy AC drive

The J1000 meets all automation requirements for compact applications with variable speed operation and energy saving characteristics. It’s just unpacking, plugging in and everything runs smooth.

J1000 Benefits and Features

• Ultra-compact size AC drive running induction motors

• Fast stop without braking resistor with overexcitation braking

• Boost function detects load and automatically adjusts torque

• Operates one size larger motor in normal duty

• Speed search function for smooth start-up of coasting motors

• Built-in braking resistor

• Space saving and compact design

• Easy and time-saving start-up

• Outstanding reliability

• Capacitors for 10 years of maintenance-free operation

• Ultra-compact AC drive for controlling asynchronous motors

Applications for the J1000

The J1000 AC drive is a user-friendly plug-and-play solution for energy saving motor control in various application areas.

• Pumps

• Conveyors

• Fans

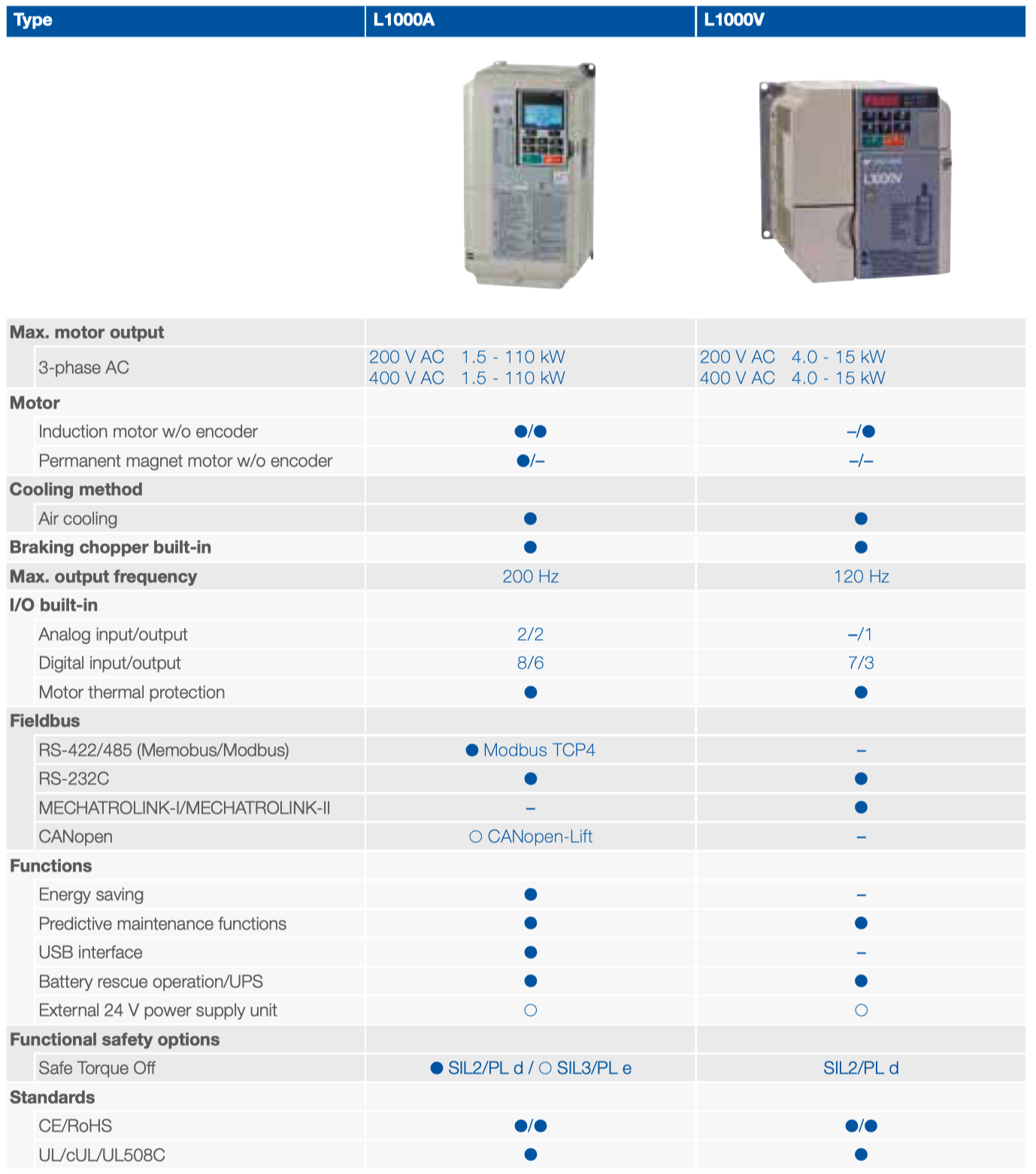

L1000 Solutions for the lift industry

The L1000 lift AC drives meet the latest requirements for elevator solutions and are equipped with intelligent high-performance functions especially for lift and elevator applications. Experience the characteristic YASKAWA reliability in combination with maximum ride comfort.

Lift packages with AC drives and motors

Together with the L1000A AC drive, the MSYP-160 and MSYP-200 motors are the ideal solution for lifts without machine room.

Up to 2500 kg with a speed of 2 m/s

• Perfect match for the chosen motor and lift application

• Reliable operation

• One supplier, one order, one shipment, one guarantee

• Integrated lift functions, such as brake control, motor contactor control, short floor ride

• Automatic evacuation in light direc- tion allows smaller UPS or battery

• One motor contactor solution according to EN81 reduces cost and

increases reliability

• High performance motor control for shock-free starts, smooth rides and

accurate stops

• Simple I/Os allow connection to almost any other lift controller

• Motor data auto-tuning in standstill condition without removing ropes

(L1000A: also supports PM motors)

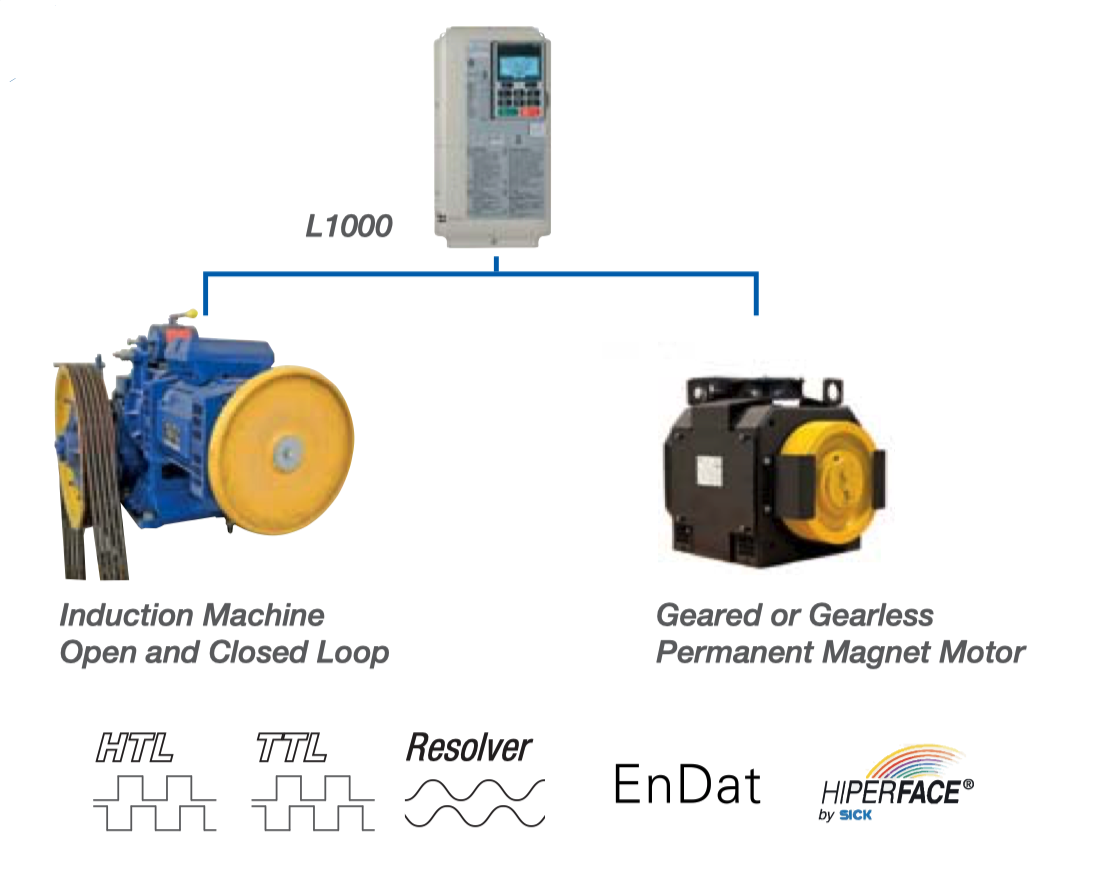

L1000A

• Drives induction and PM motors, with and without

speed feedback, geared and gearless

• Programming in lift terminology and 13 languages

• A3 brake monitoring and DCP3 interface

• Incremental, Endat, Hiperface, SinCos and Resolver

feedback

• SIL3 STO for contactorless operation

• CANopen-Lift and DCP4 interface

L1000V

• Smallest lift drive available on the market saves

space and cost on panel design

• Sensorless control of geared induction motors

with precise slip compensation for best stop

accuracy

• Programming in lift terminology and 8 languages

with optional full text LCD keypad

DON'T KEEP ON GOING ROUND AND ROUND contact us for more information about the Yaskawa range of drives Tel 02476 980833

T1000 Solutions for the textile industry

These AC drives with a wide power range from 0.1 kW to 185 kW are equipped with standard and special functions to meet all application requirements in the textile industry. The T1000 series has been specifically designed to provide reliable and cost-effective operation and ease of use.

T1000 Benefits and Features

• Finless and fanless design - Heatsink and cold plate versions for water cooler mounting available and no built-in fans

• PCB coating suitable for textile production — for highest reliability in typical textile applications

• Traverse function — for optimized yarn winding

• Power loss ride-through function: safe operation status at all times, especially for synchronized drives with shared DC link

• Outstanding reliability with long life design for 10 years of maintenance

free operation

T1000A

• Simple and effective speed synchronization within a production line with pulse train output and pulse train speed setpoint

• High-precision open and closed-loop control of asynchronous and

permanent magnet motors

• No fans needed on Coldplate models

• Special software for the textile industry

Applications

The T1000 AC drive series is optimally protected from dust and other contaminants, making it ideal for use in the textile industry:

• Spinning

• Winding

• Washing

• Weaving

• Fiber preparation

T1000V

• Encoderless control of induction and permanent

magnet motors

• Compact design with an output of up to 18.5 kW

• Single-phase model available

• Integrated textile know-how

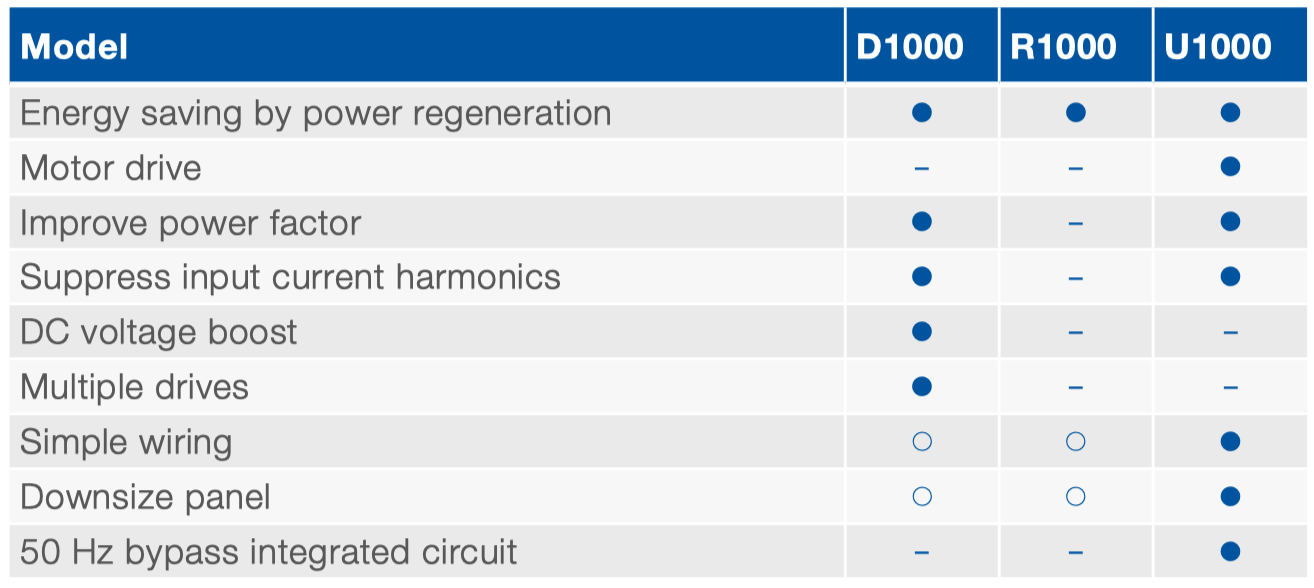

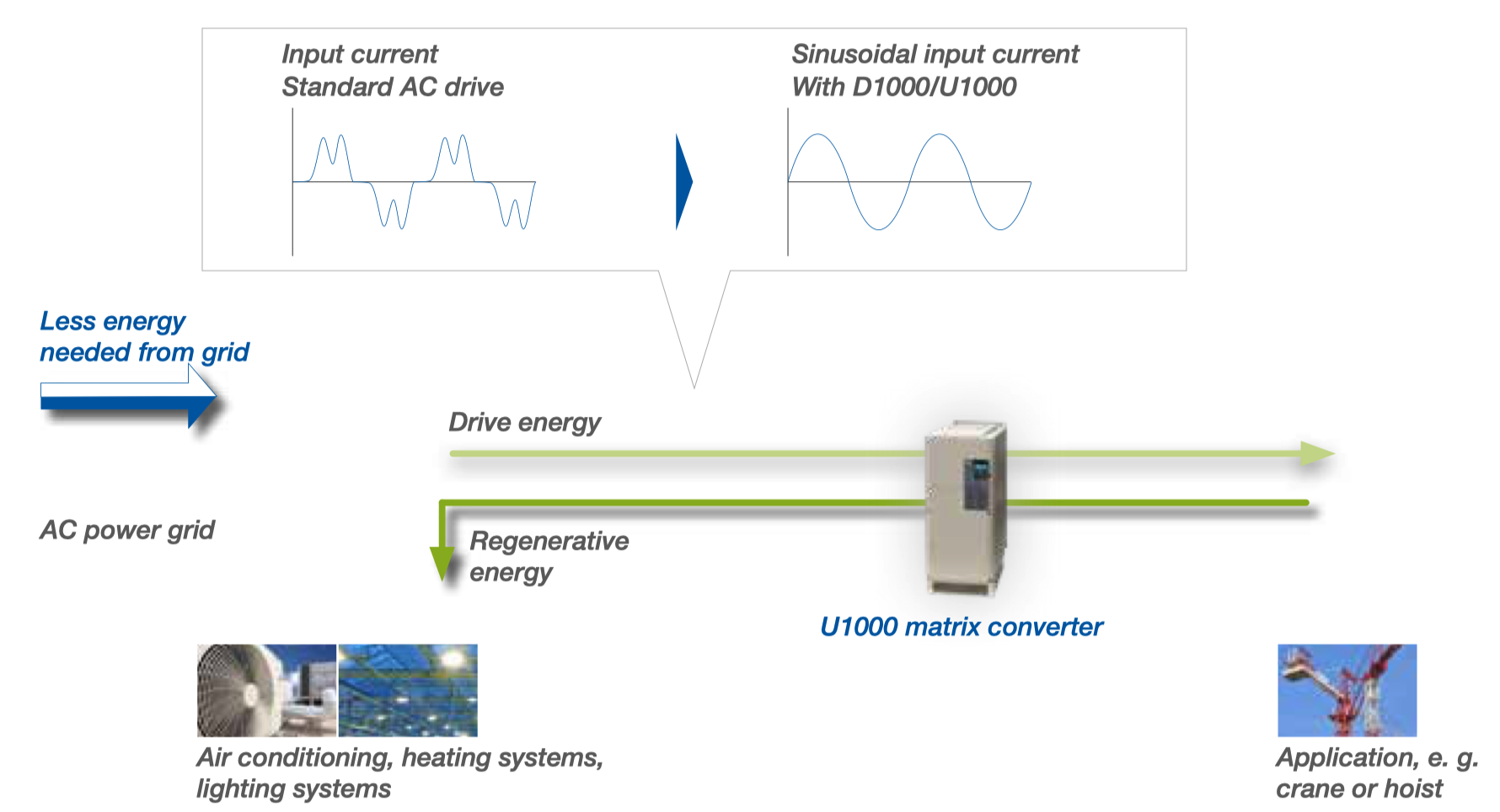

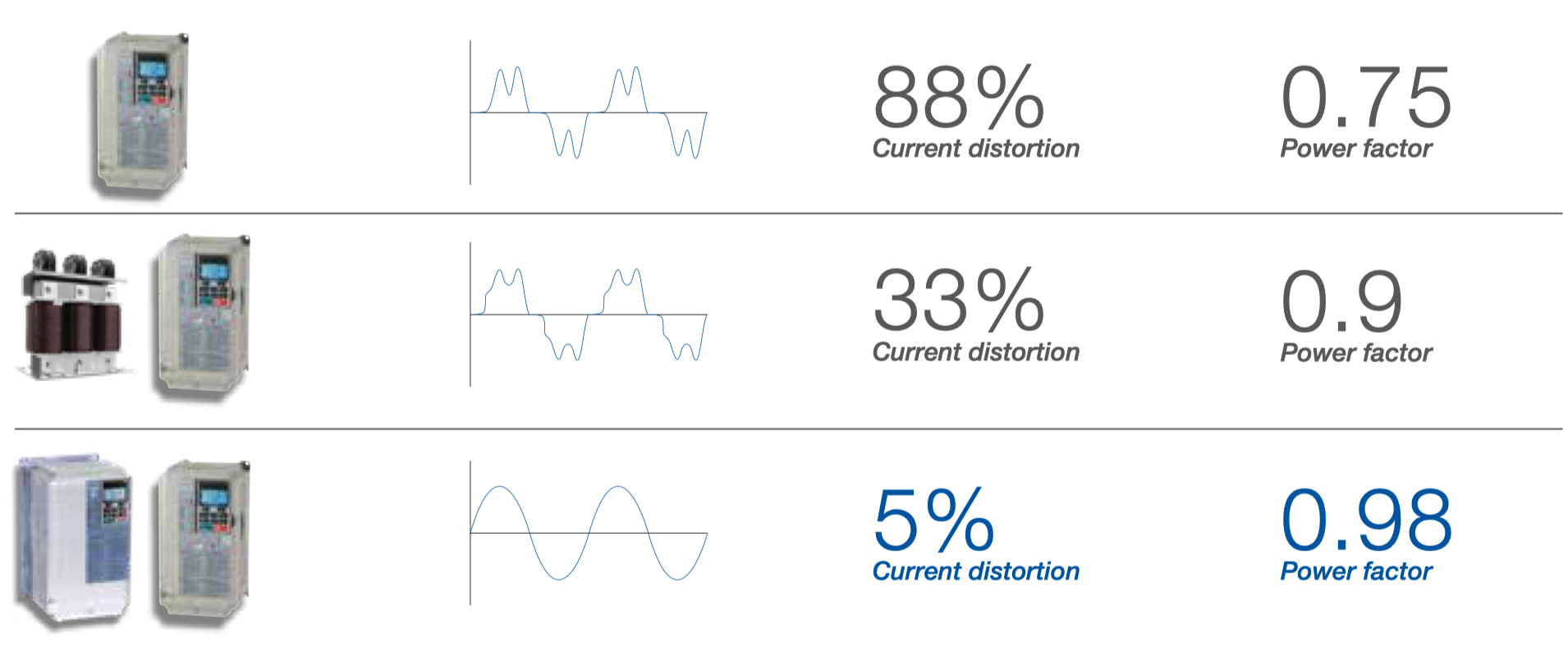

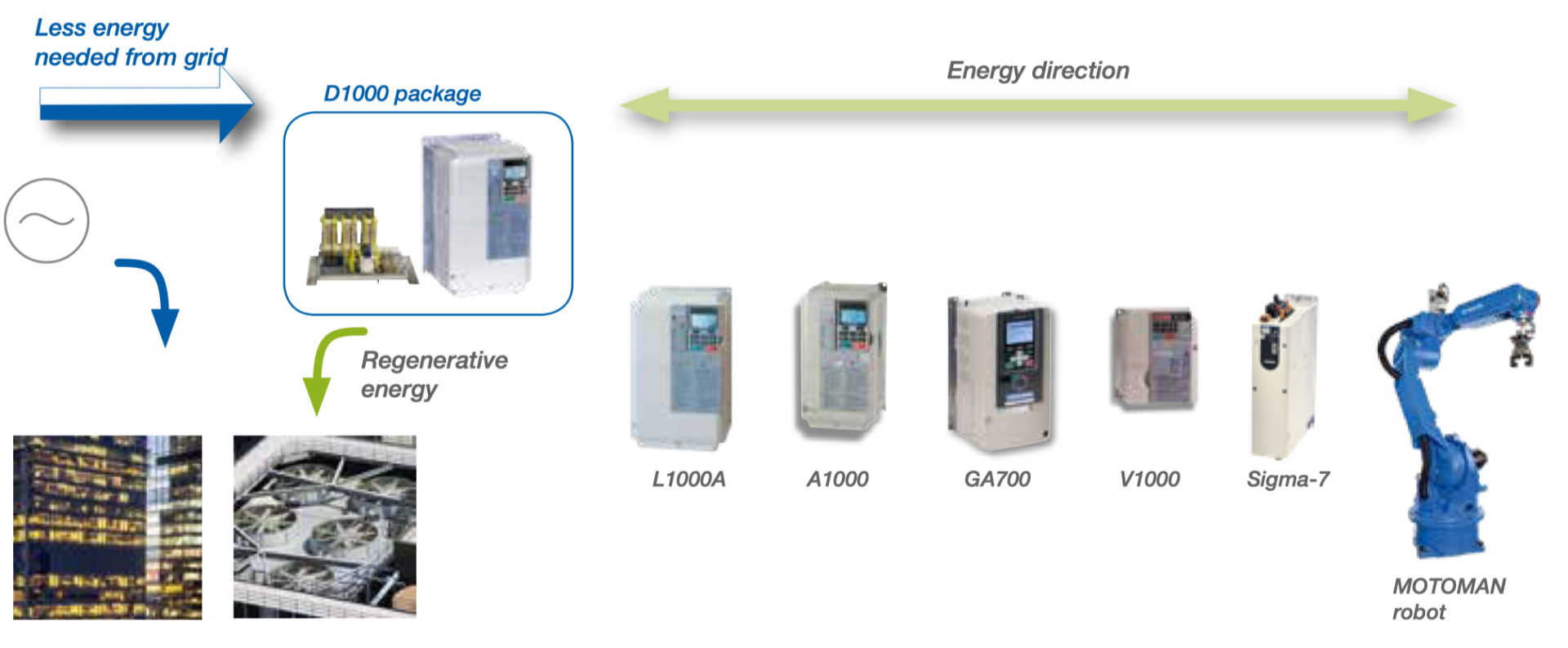

Grid quality and energy recovery

YASKAWA offers customer-friendly solutions with the U1000 matrix converter, the D1000 regenerative converter unit and the R1000 regenerative unit, which can make a significant contribution to reducing power consumption by feeding braking energy back into the power grid. This reduces costs and ensures

efficient operation.

You too can benefit from a solu- tion that meets the requirements of the most diverse applications.

* An additional AC drive is required for the D1000.

The ideal energy-saving solution for your application with U1000 matrix converter

DON'T KEEP ON GOING ROUND AND ROUND contact us for more information about the Yaskawa range of drives Tel 02476 980833

The ideal energy-saving solution for your application with D1000 regenerative converter unit

Energy-saving solutions

D1000 regenerative converter unit

The D1000 regenerative unit saves both power and space. It is suitable for individual regenerative AC drives as well as for systems of AC drives, servo axes or robots.

It feeds excess braking energy back into the power grid instead of converting it to heat. The DC voltage amplification function increases the reliability of the system even when variable or fluctuating input voltages are present.

• Constant sinusoidal input and feedback

• No distortion of the input voltage

• Stable intermediate circuit voltage

• DC gain

• Very low harmonics

• Common DC bus for several AC drives

Areas of application

• Motor test benches

• Robots

• Winders

• Elevators and escalators

• Fans

• Pumps

• Compressors

R1000 regenerative unit

The R1000 regenerative unit with block circuit is an environmentally friendly, sustainable alternative for braking re- sistors.

Compared to conventional solutions, the R1000 regenerative unit saves space and reduces maintenance work. The energy fed back into the grid also contributes to cost savings and at the same time protects the environment!

• Regenerative unit with a wide power range:

200 .. 240 VAC 3.5 to 110 kW

380 .. 480 VAC 3.5 to 300 kW

• Suitable for 4-quadrant operation without braking resistors

• Eliminating braking resistors saves space and simplifies installation

• Less cooling required for the control cabinet because no heat is generated by resistors

• Recovered energy can be made available to other consumers in the plant, thus reducing the total energy consumption of buildings or factories

• Quick amortization of initial costs

• Proven YASKAWA quality

Areas of application

• Test benches

• Fans

• Transportation systems

• Cranes and hoists

• Elevators

• Blowers

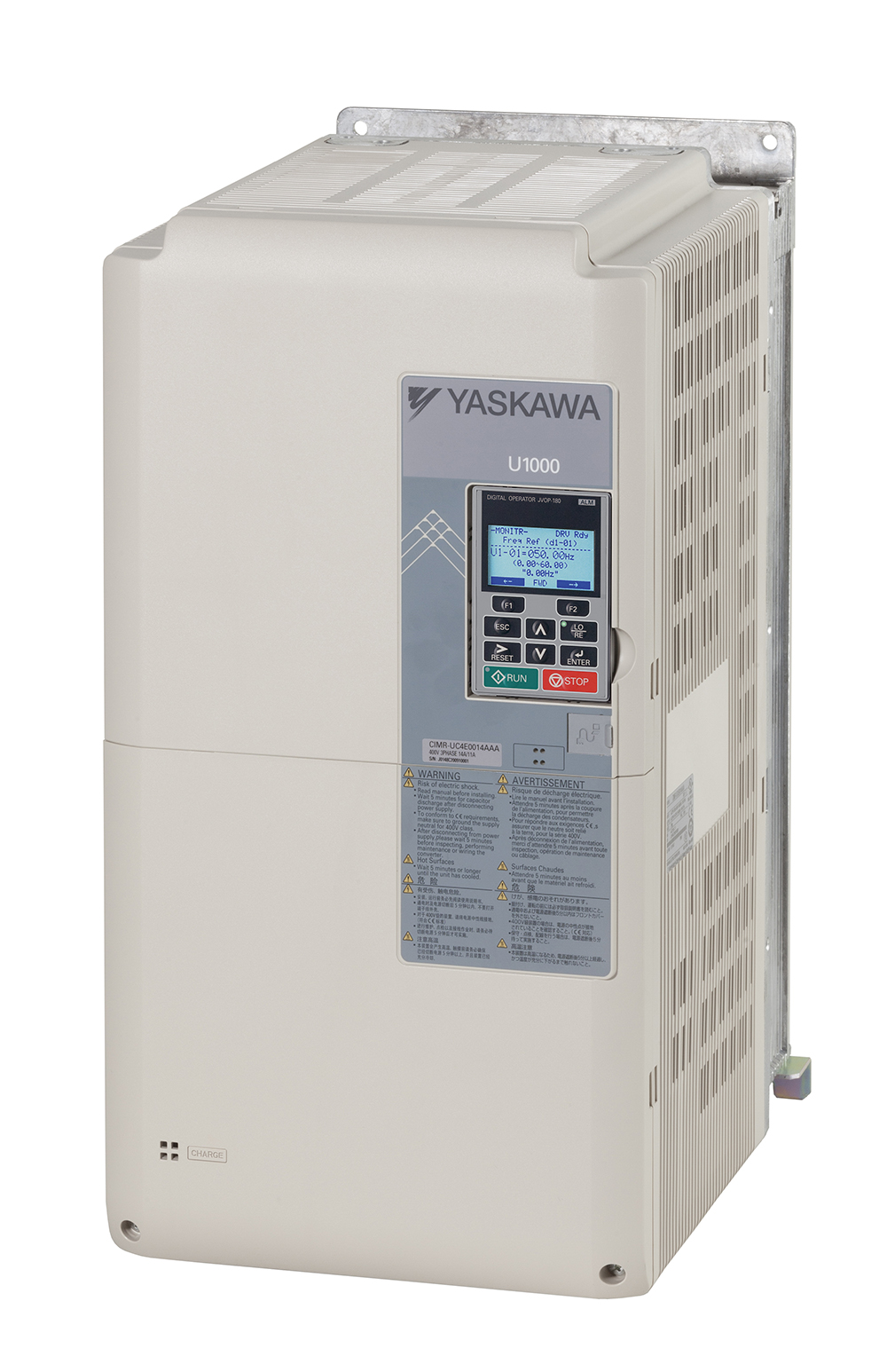

U1000 Matrix converter

The matrix converter is an energy- efficient AC drive without DC link. It feeds regenerative braking energy back into the power grid, while the sinusoidal input voltage reduces power loss and enables efficient operation.

• Precise control of asynchronous and permanent magnet motors with or without encoder

• Highly efficient direct AC/AC conversion

• Extremely compact design

• Very low harmonics (THDi < 5%)

• Simple connection and user-friendly auto-tuning function for fast and smooth commissioning

• Integrated functional safety (STO, SIL3)

• Integrated EMC filter, external components such as chokes are not required

• Integrated bypass circuit at 50 Hz

• Low heat generation due to no DC link

• Four quadrant AC drives for regenerative and motor applications Key Featuresin one unit

Key features

The matrix converter is an energy- efficient AC drive without DC link. It feeds regenerative braking energy back into the power grid, while the sinusoidal input voltage reduces power loss and enables efficient operation.

• Precise control of asynchronous and permanent magnet motors with or without encoder

• Highly efficient direct AC/AC conversion

• Extremely compact design

• Very low harmonics (THDi < 5%)

• Simple connection and user-friendly auto-tuning function for fast and smooth commissioning

• Integrated functional safety (STO, SIL3)

• Integrated EMC filter, external components such as chokes are not required

• Integrated bypass circuit at 50 Hz

• Low heat generation due to no DC link

• Four quadrant AC drives for regenerative and motor applications in one unit

Applications

• Escalators

• Cranes, hoists

• Conveyors

• Lifts

• Centrifugal separators

• Ship winches

• Test benches

• Presses

• Limitation of network harmonics

AC drives comparison

Lift solutions

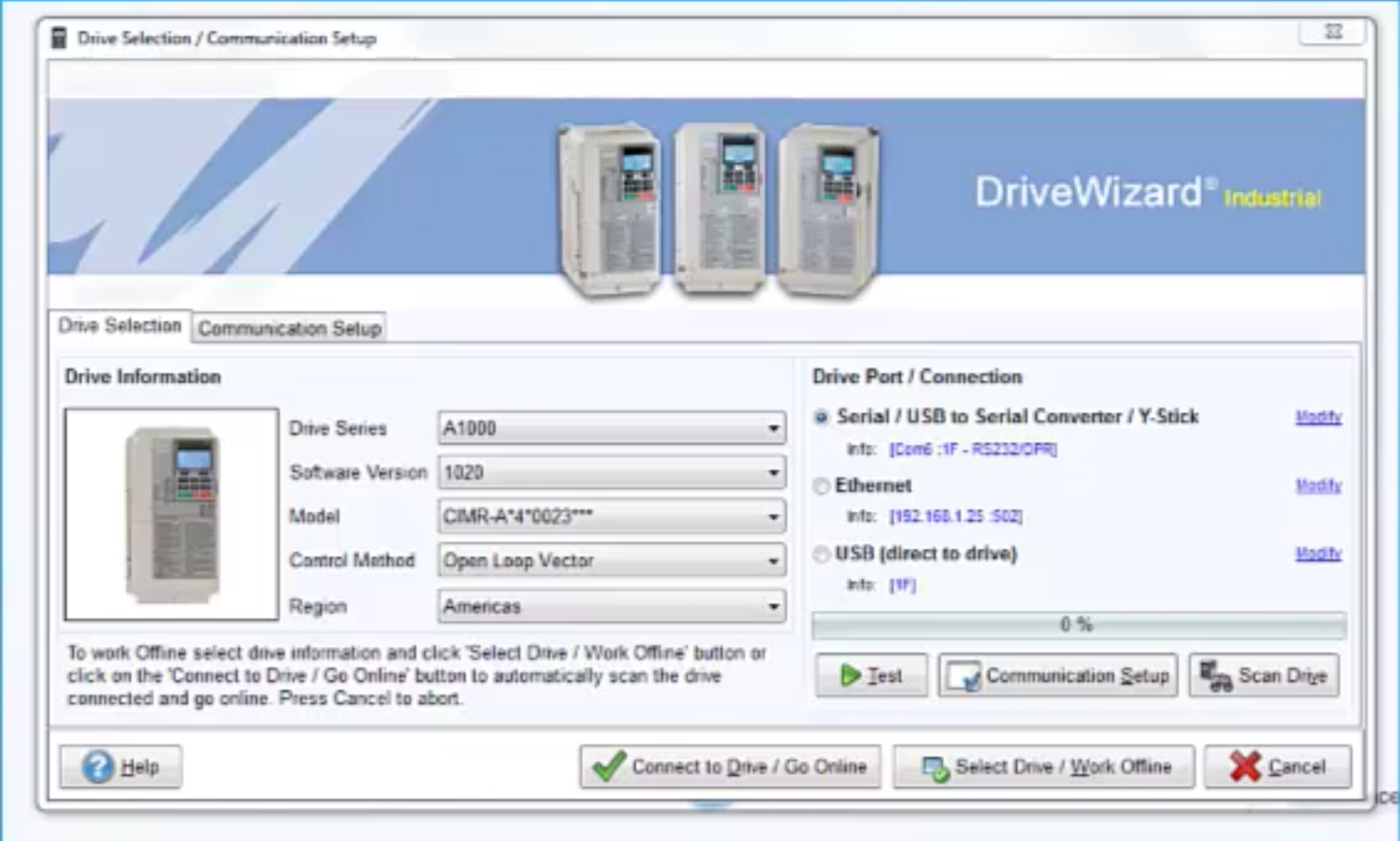

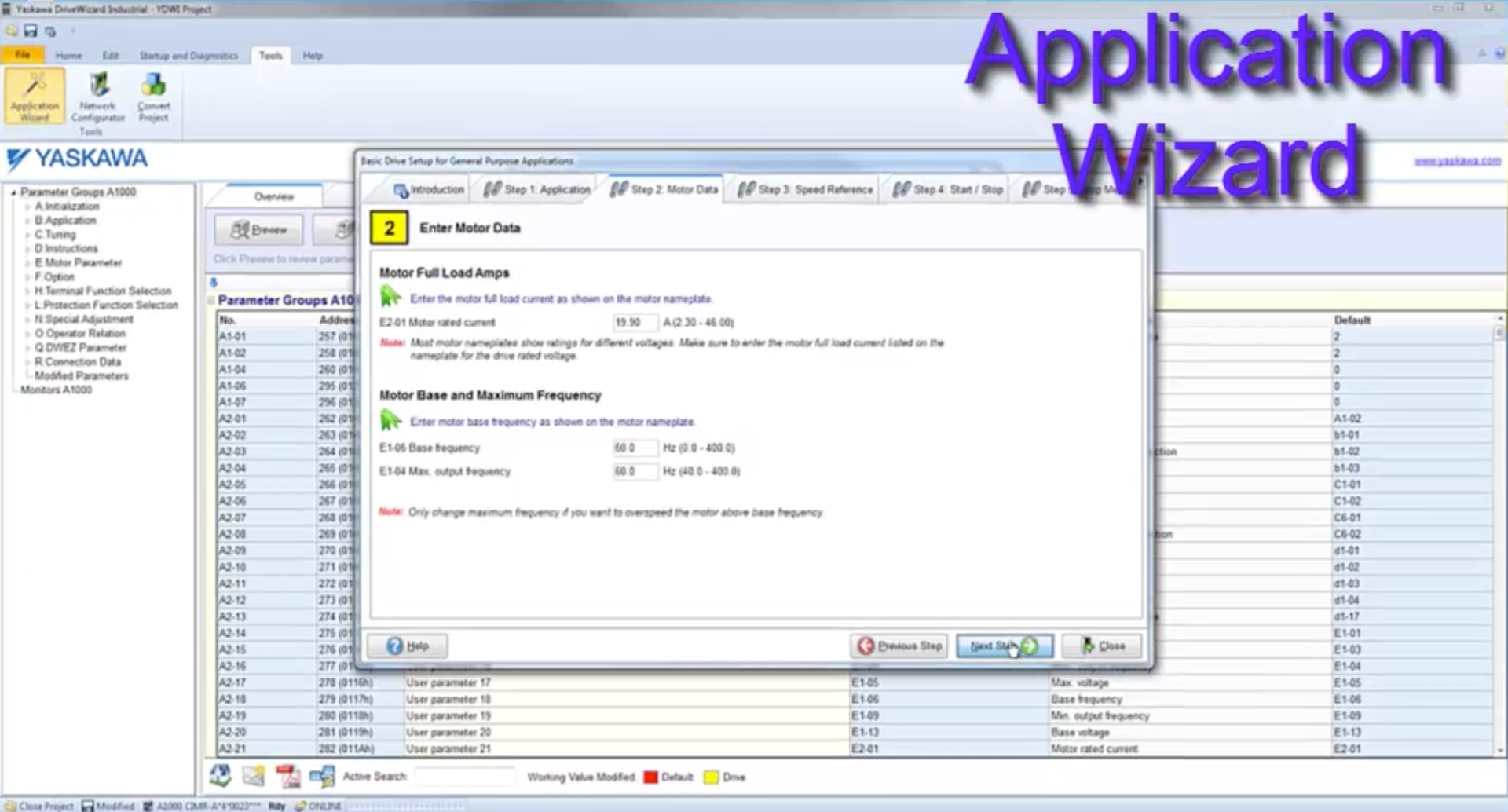

DriveWizard Plus for easy engineering

Manage the unique settings for all your drives right on your PC. An indispensable tool for drive setup and maintenance.

Edit application parameters, access all monitoring parameters, generate customized process flows and monitor the performance of the AC drives using the oscilloscope function.

• Automatic parameter conversion from older series drives

• Convenient PC-based drive-setup, monitoring and diagnostic functions

• Online and offline parameter editing

• Built-in oscilloscope function

DriveWorksEZ for programming

DriveWorksEZ® provides users with programmable functions to customize GA700, V1000 and A1000 series AC drives to their specific applications without the need for external control systems such as PLCs. This allows users to easily access the drives via a symbol-based graphical programming environment.

• PLC or other controllers not necessary

• Easy to use

• Fast and constant scan cycles

• Flexible

• On-line monitoring

• Process control

• Protected application know-howExamples

Examples

Economically optimized water skiing facility

• No additional I/Os necessary

• No PLC required - reduced the system cost to less than 50% of the initial estimate

Highly precise positioning

• Direct access to encoder pulses

• User-defined units and monitors

Further examples

• Efficient Brake Sequence

• Unbalance Detection in Washing Machines

Options and accessories

The YASKAWA AC drives can be connected to all major bus systems. By default RS-232C and RS-422/485 (Memobus/Modbus) is supported.

Additional option cards allow easy connection to almost any network or PLC.

Customizable with Options and Accessories.

YASKAWA provides a wide range of accessories and options. In addition to drives, YASKAWA provides all major options and accessories needed in systems, be it for standards compliance, connectivity or protective design.

• AC input reactors

• EMC filters - standard versions and IT grid filters

• Chokes for applications such as lifts and escalators

• Harmonic filters

• Sine wave output filters

• Control panels as LED version (7-segment display) or LCD plain text display for 13 languages, or with Bluetooth function

• 24 V control power supplies

• USB copy units

• Communication option cards

• I/O option cards

• Speed feedback option cards

• Mechanical options for improved

drive protection

• Braking options

• Motor reactors

DON'T KEEP ON GOING ROUND AND ROUND contact us for more information about the Yaskawa range of drives Tel 02476 980833

A1000 and P1000 are also offered in configured and engineered drive packages that mount the drive inside a NEMA/UL Type 1, 12, or 3R enclosure with space for various commonly used options. Yaskawa’s latest addition is the U1000 Industrial Matrix Drive.

With the U1000, Yaskawa incorporates innovative technology into a low-voltage matrix converter to directly convert input AC voltage to output AC voltage. It is ideally suited for industrial applications that require extremely low harmonic distortion, energy savings, safety, and serviceability in a space-saving design.